FLOWFORMING

FLOWFORMING TECHNOLOGIE BY ATS

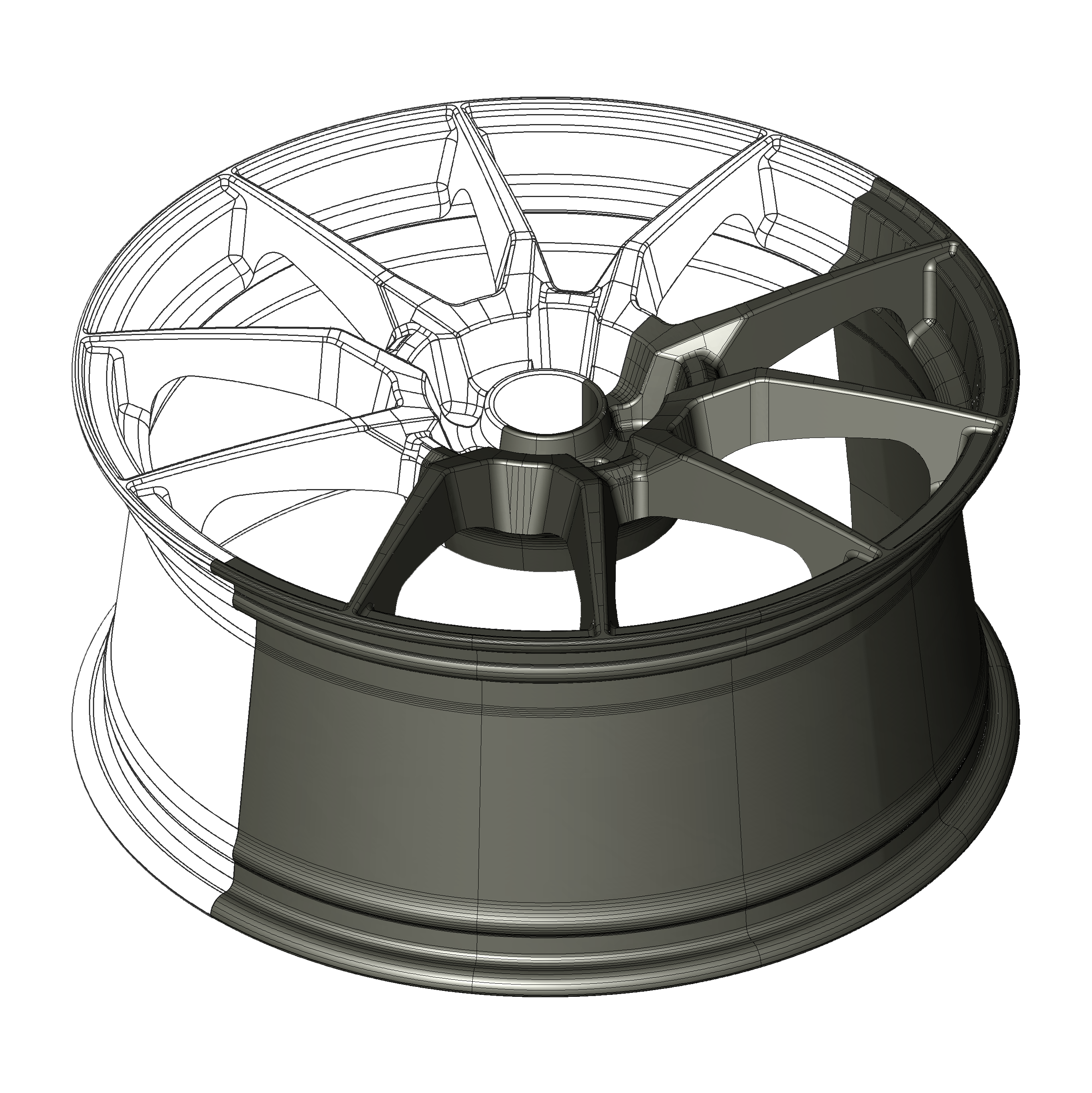

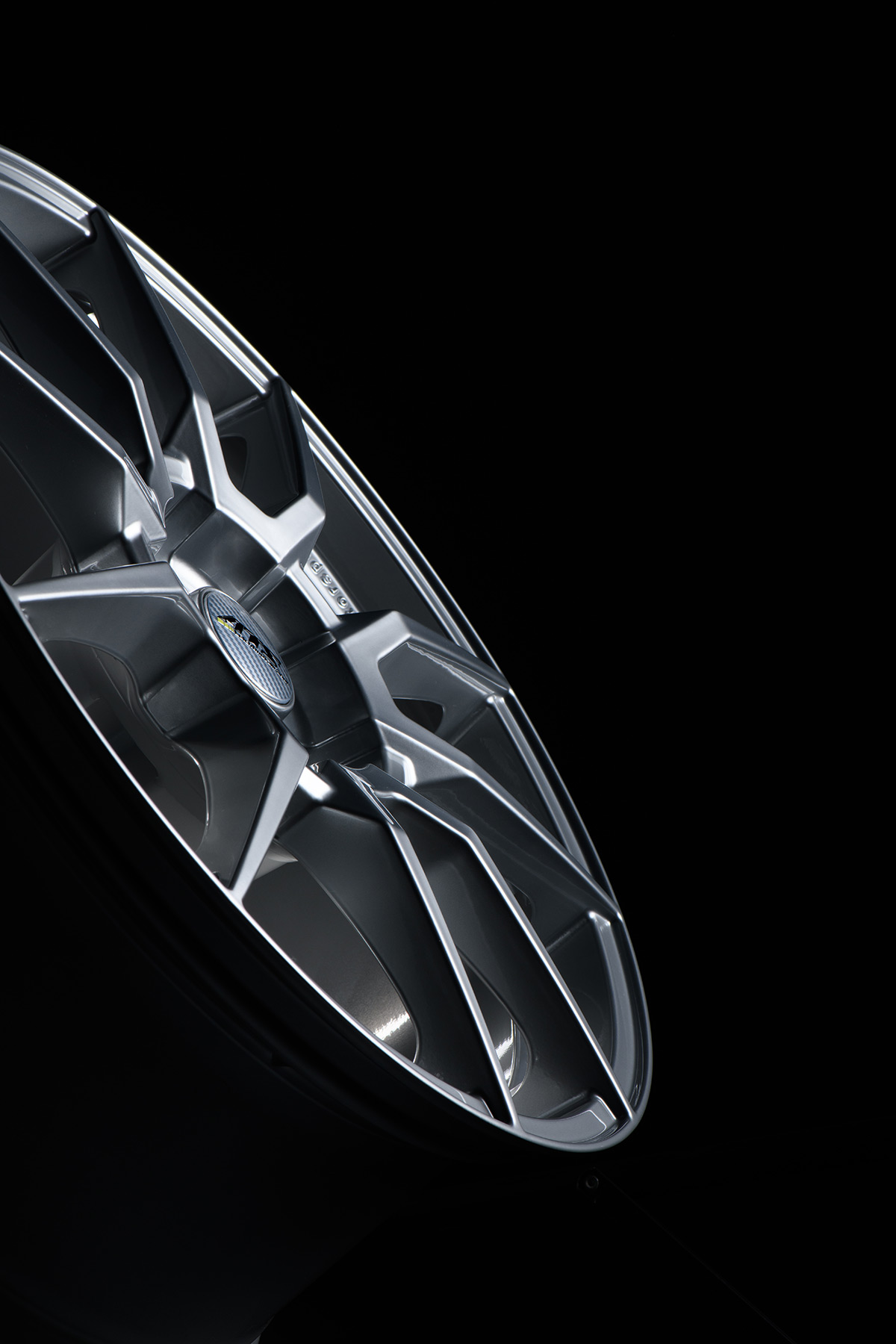

FlowForming by ATS – eine Technologie und innovative Fertigungsvariante, die das Beste aus zwei Welten vereint. Denn dank des angewandten Gussverfahrens behalten wir uns nicht nur die absolute Freiheit in Sachen Gestaltung bei, wir optimieren auch noch das Baugewicht unserer Räder, ohne dabei an Festigkeit und Stabilität zu verlieren.

Geht nicht, denken Sie? Doch – FlowForming by ATS macht es möglich.

DAS PRODUKTIONSVERFAHREN – WIE FUNKTIONIERT FLOWFORMING BY ATS?

FlowForming by ATS – eine Technologie und innovative Fertigungsvariante, die das Beste aus zwei Welten vereint. Denn dank des angewandten Gussverfahrens behalten wir uns nicht nur die absolute Freiheit in Sachen Gestaltung bei, wir optimieren auch noch das Baugewicht unserer Räder, ohne dabei an Festigkeit und Stabilität zu verlieren.

Geht nicht, denken Sie? Doch – FlowForming by ATS macht es möglich.

DIE FLOWFORMING TECHNOLOGIE BY ATS BRINGT MIT SICH VIELE VORTEILE

Durch die FlowForming Technologie by ATS spart man nicht nur Rohstoffe und damit auch Gewicht ein, man ermöglicht gleichzeitig eine geringere Wandstärke, ohne Stabilität zu verlieren – ein entscheidender fahrdynamischer Vorteil. Bei großen Rädern kann man sage und schreibe bis zu 8kg Gewicht pro Fahrzeug einsparen. Dieses geringere Gewicht verhilft zusätzlich dazu, die Emission deutlich zu reduzieren.

SOCIAL MEDIA