FLOWFORMING

FLOWFORMING TECHNOLOGY BY ATS

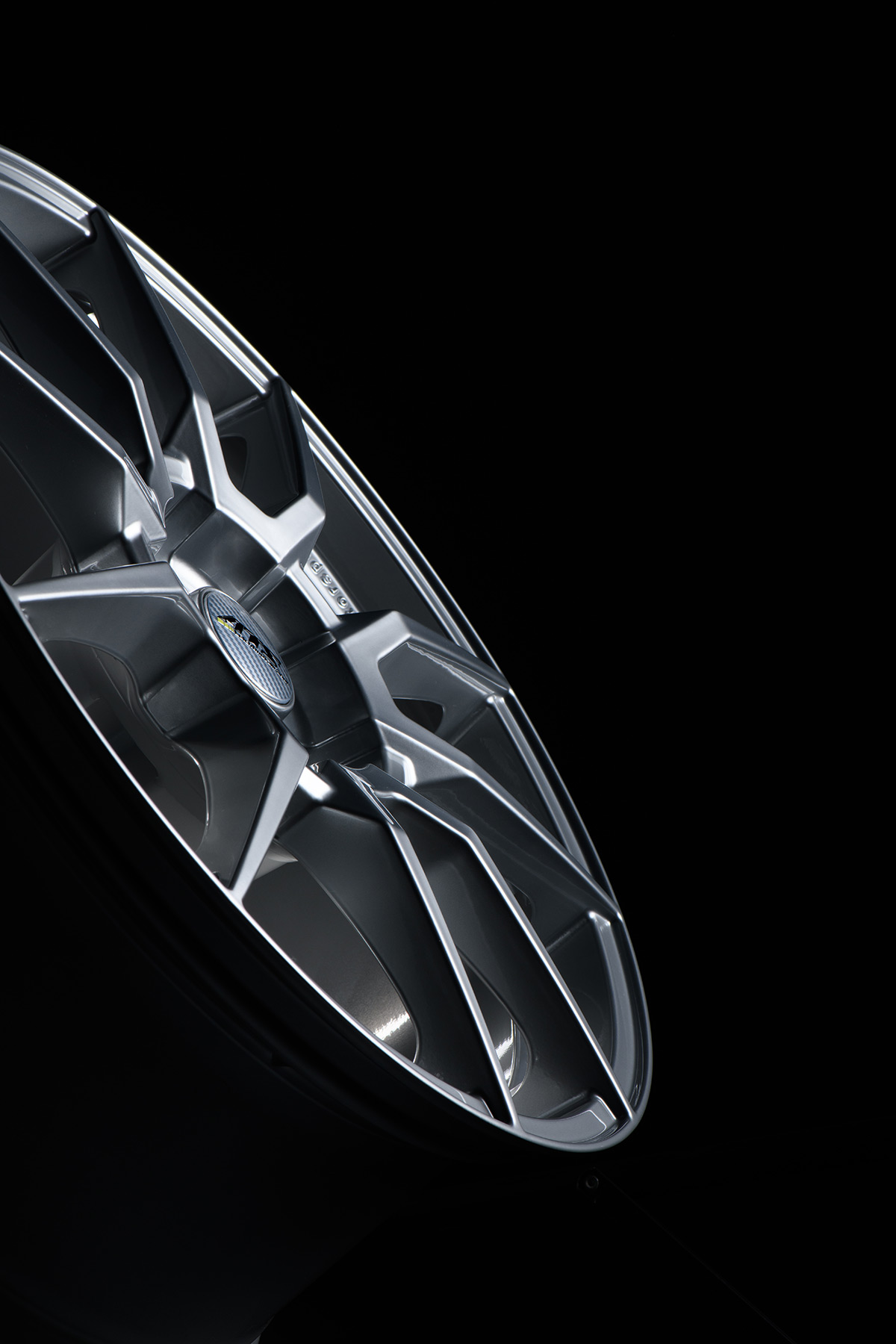

FlowForming by ATS – a technology that combines just the best out of two different worlds. This innovative production process maintains the advantages of casting production, such as the design flexibility, and at the same time ensures optimization of weight, resistence and stability.

You think that is not possible? It is – FlowForming Technology by ATS makes it possible.

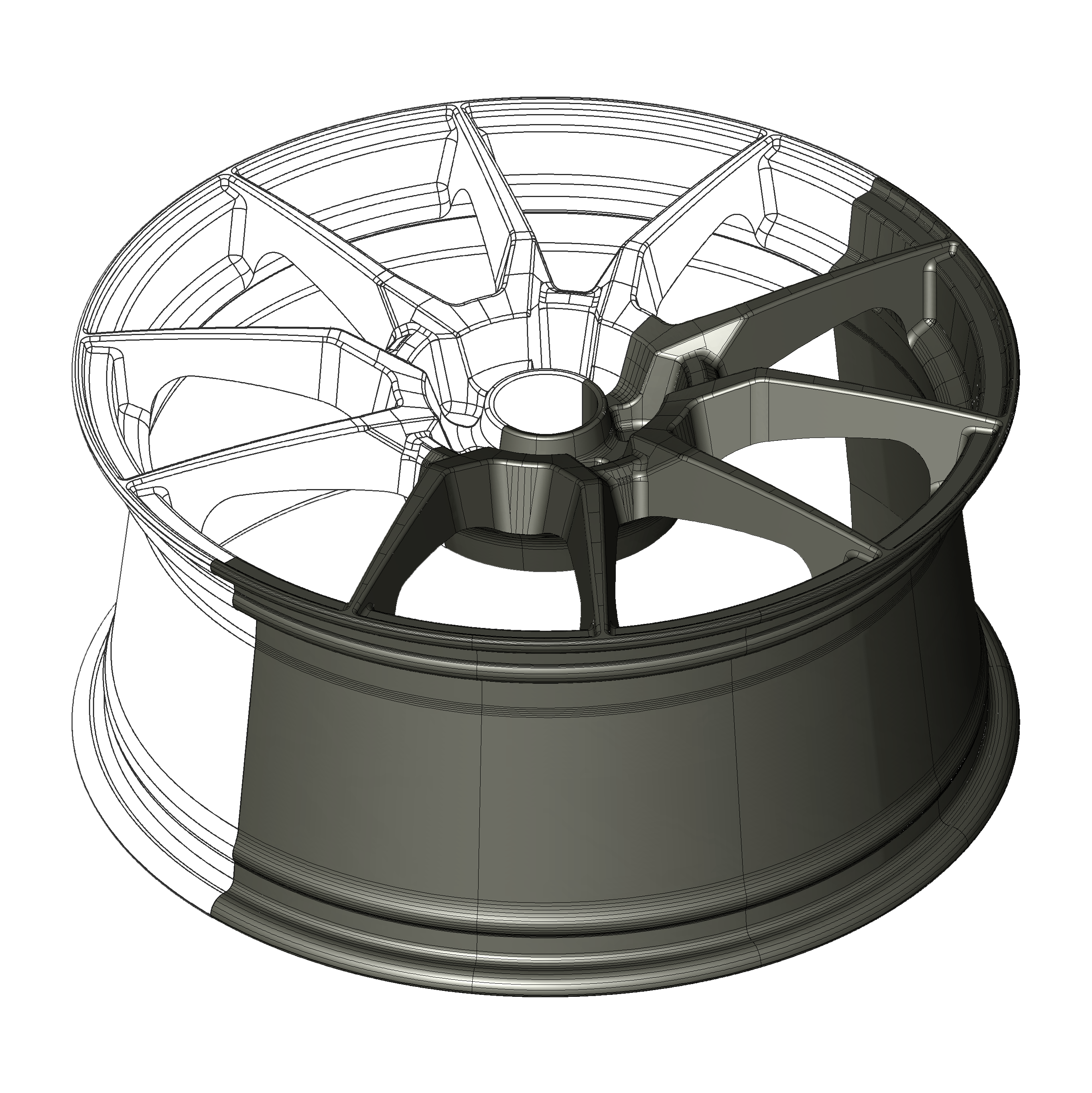

THE PRODUKTION PROCESS – HOW EXACTLY DOES FLOWFORMING BY ATS WORK?

How to imagine the FlowForming production process? To put it as short as possible: parts of the cast alloy wheels get heated to approximately 350 degrees, „rolled-out“ and thereby compressed. To enable this process and to achieve the desired shape, we stretch the wheel blank over a rotating cylinder. The rolling heads, which are pressed against the blank from the outside with high pressure ( approximately 100 tonnes) and are slowly moving downwards, are also rotating. That process obviously is responsible for the technology’s name: FlowForming.

FLOWFORMING TECHNOLOGY BY ATS – BENEFITS AND ADVANTAGES

Durch die FlowForming Technologie by ATS spart man nicht nur Rohstoffe und damit auch Gewicht ein, man ermöglicht gleichzeitig eine geringere Wandstärke, ohne Stabilität zu verlieren – ein entscheidender fahrdynamischer Vorteil. Bei großen Rädern kann man sage und schreibe bis zu 8kg Gewicht pro Fahrzeug einsparen. Dieses geringere Gewicht verhilft zusätzlich dazu, die Emission deutlich zu reduzieren.

SOCIAL MEDIA